Packaging Solutions That Grow with Your Business

From a single Variable Packaging Solution (VPS) to fully automated packaging lines, we offer custom solutions engineered for your specific requirements.

As a driver of innovation in machine and plant engineering, Kraft Machines Inc. delivers highly flexible packaging systems tailored to your application and long-term growth strategy. Whether you’re starting with a standalone machine or a complete plant, we ensure seamless integration for reliable, scalable performance.

Working closely with our customers, we plan and engineer custom solutions designed for multi-shift industrial use. All machines and components are built for durability, easy maintenance, intuitive operation, and low operating costs, helping you increase efficiency and reduce labor over time.

Let’s build a packaging system that meets your needs today and evolves with your business tomorrow.

Request Custom Packaging Solution Quote

Custom Packaging Systems & Automated Packaging Lines

From single packaging machines to fully automatic packaging lines, we offer customized packaging systems and components for diverse applications:

Flat parts and panels

- Shower wet walls

- Work surfaces

- Shelving

- Countertops

- Garage door panels

Long and narrow products

- Skis

- Siding

- Window shades

- Sensors and electrical components

- Furniture (disassembled – RTA/assembled)

- Kitchen elements

- Doors and frames

- Construction elements

- Insulation materials

- Radiators and other industrial products

- Fulfillment

- And more custom packaging applications

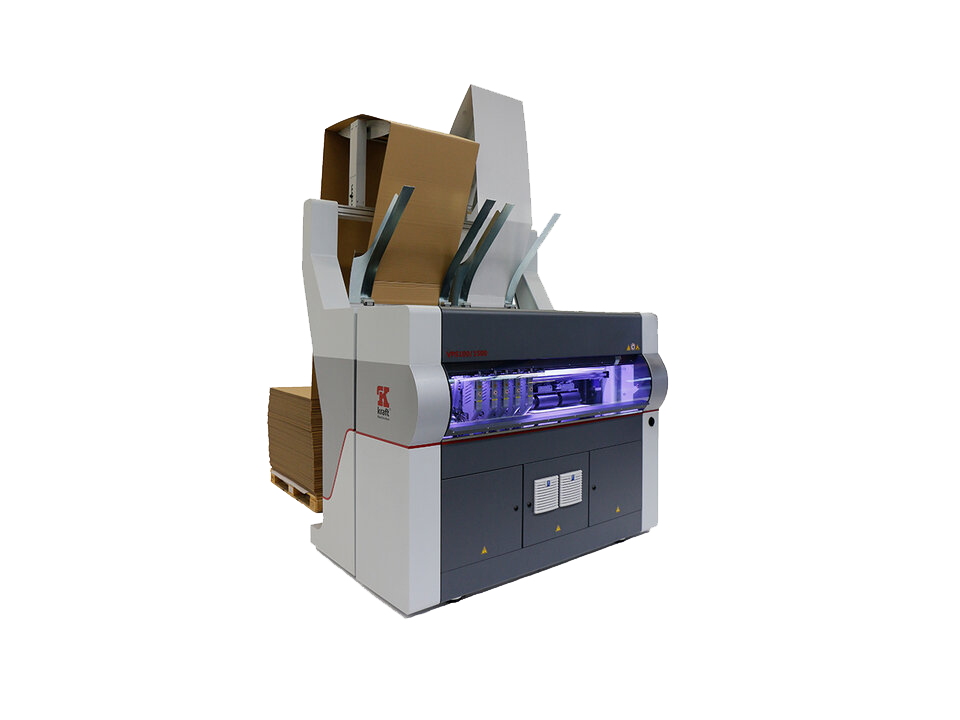

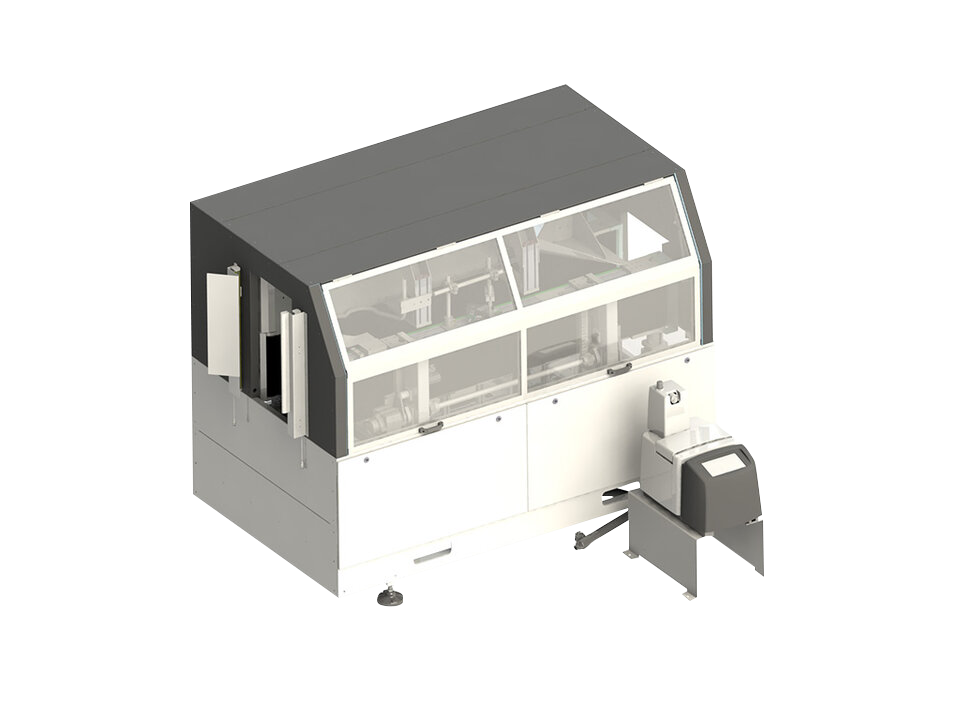

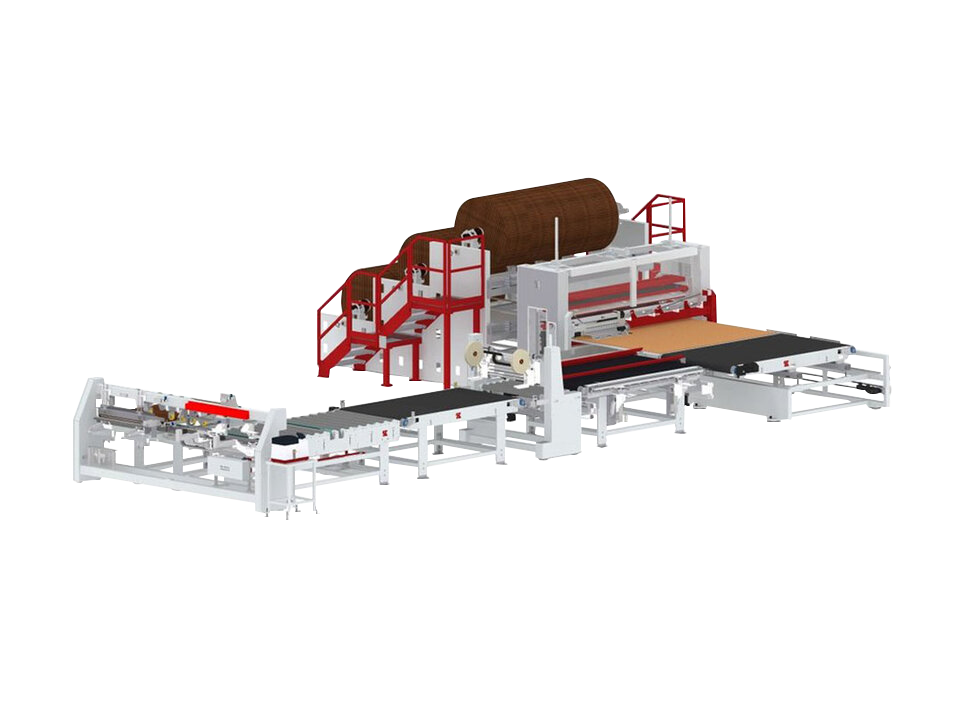

VPS100 Corrugated Cutting Machine – Precision & Flexibility for Cardboard Packaging

The VPS100 is Kraft Machines Inc.’s top solution for automated corrugated cutting and custom box production. With advanced servo technology, it delivers fast, accurate, and flexible cutting for a wide range of packaging needs.

Key Features:

- Multi-Function: Cuts, creases, and perforates cardboard in a single pass.

- Flexible: Instantly adapts to new box sizes and designs — ideal for changing production needs.

- Digital Workflow: Integrates with ERP/MES systems for seamless, just-in-time packaging.

- Efficient: Reduces material waste and lowers costs by producing only what you need.

Advantages:

- Cost Savings: Optimized processes and material usage reduces overall packaging costs.

- Maximum Flexibility: Free choice of cardboard packaging formats for diverse product needs.

- Space Efficiency: Minimized storage requirements thanks to on-demand, right-sized packaging.

- Superior Product Protection: High-quality, optimized packaging ensures reliable protection during transport and storage.

- Sustainability: Environmentally friendly, volume-optimized mono-material packaging supports your green initiatives.

- Energy Efficiency: Significant energy savings compared to traditional shrink-wrapping methods.

- Custom Packaging Design: KraftBoxDesigner software enables individual packaging designs with no ongoing software fees.

- Modular Integration: Scalable from stand-alone machines to fully automated production lines.

- Easy Operation & Maintenance: Step-by-step training videos and intuitive HMI simplify setup and upkeep.

- Flexible Financing: Multiple purchase and leasing options to fit your business needs.

Packaging Machine Components

VPS100 Corrugated Cutting Machine

Precision & flexibility for cardboard packaging.

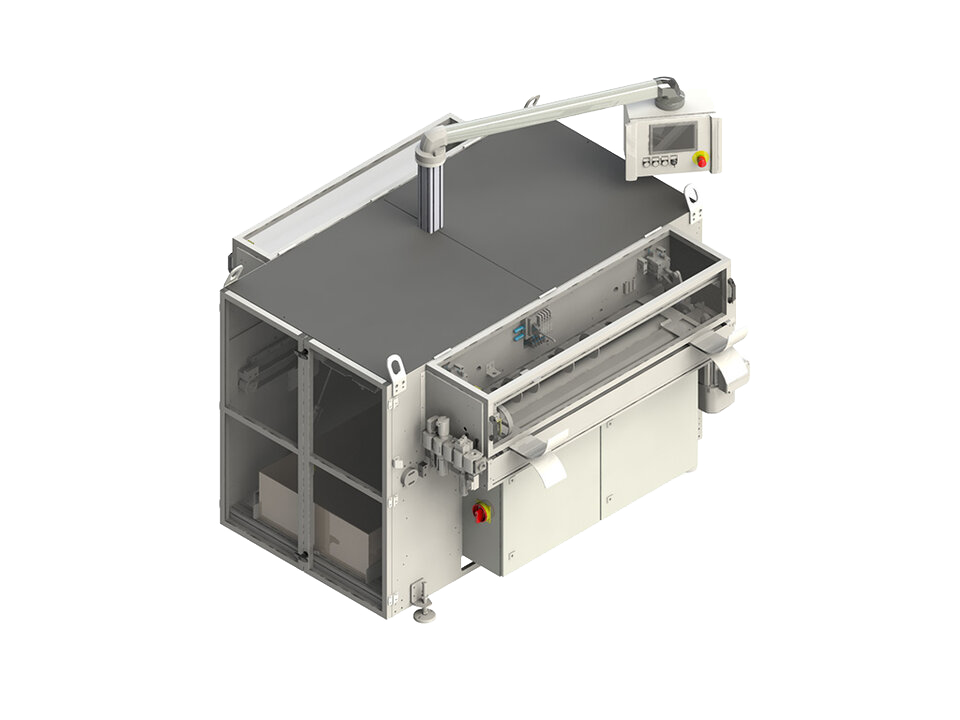

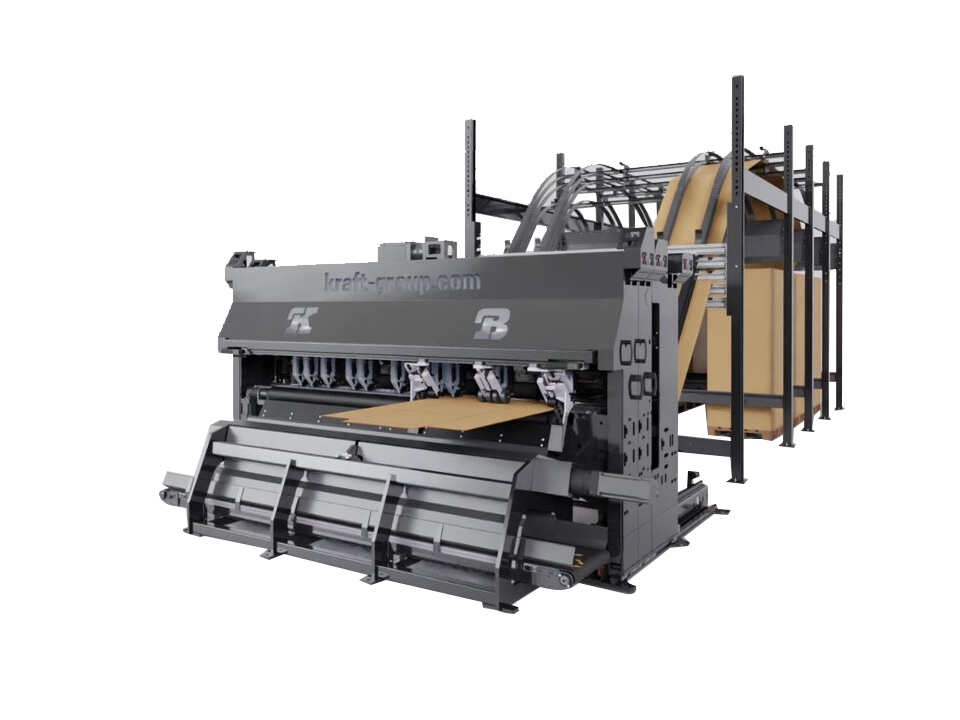

ConSta Packaging Systems

Reliable packaging machinery solutions for consistent packaging performance.

Cutting Machine Solutions

Precision cutting equipment for custom packaging applications.

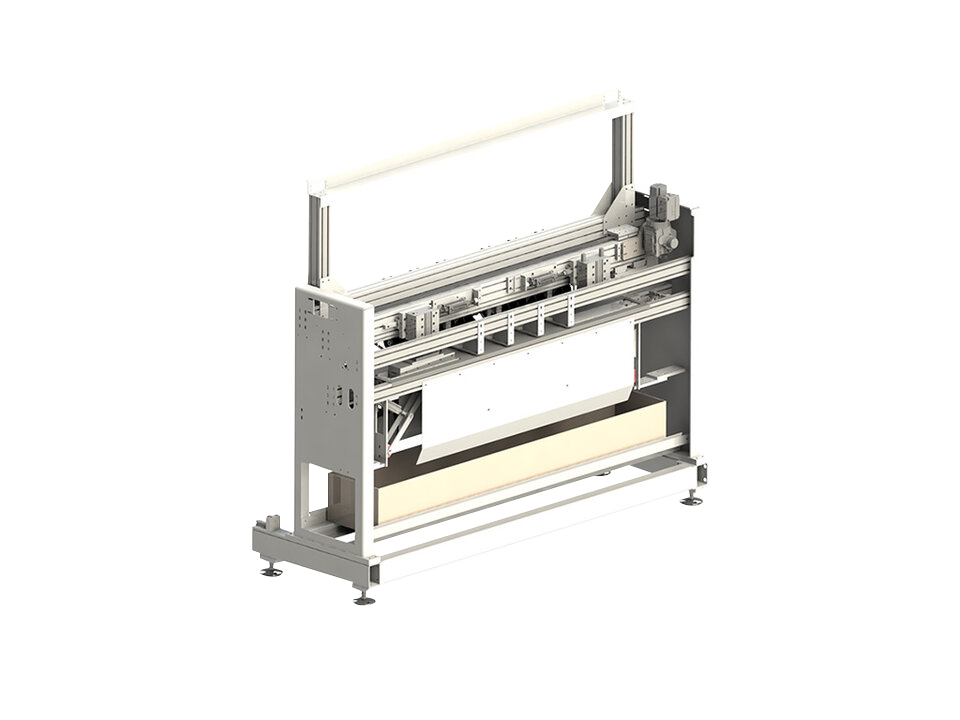

Cross Cutter Systems

Efficient cross-cutting solutions for packaging material processing.

Folding Table Equipment

Specialized folding solutions for packaging workflow optimization.

Hot Gluing Systems

Industrial-grade adhesive application for secure packaging.

Box Sealing Machines

Automated box sealing solutions for packaging line efficiency.

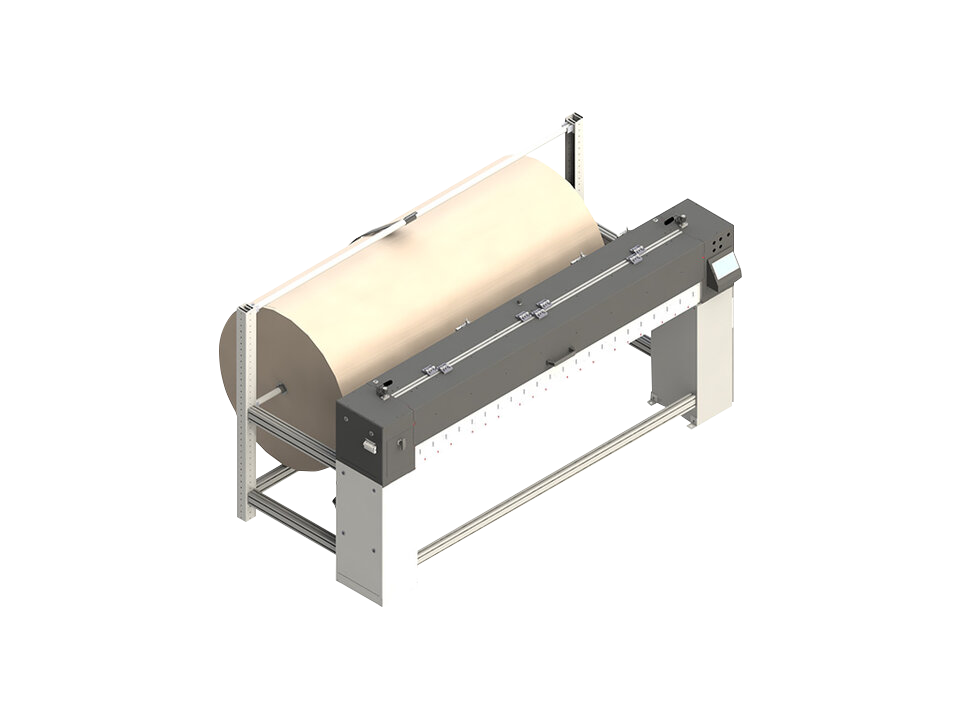

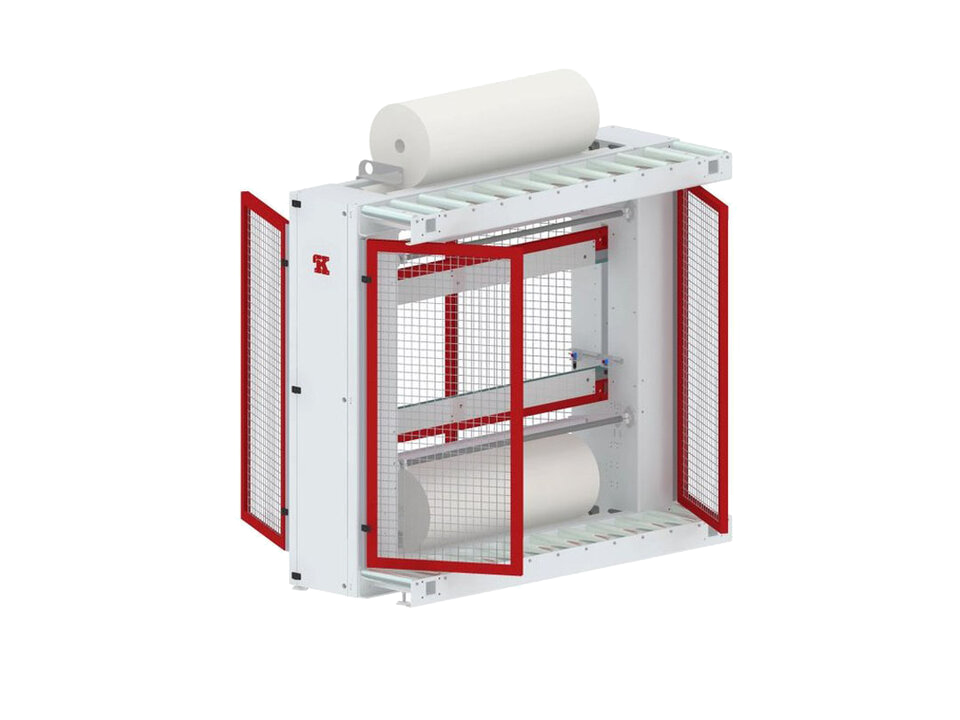

Film Packaging Equipment

Flexible film packaging systems for product protection.

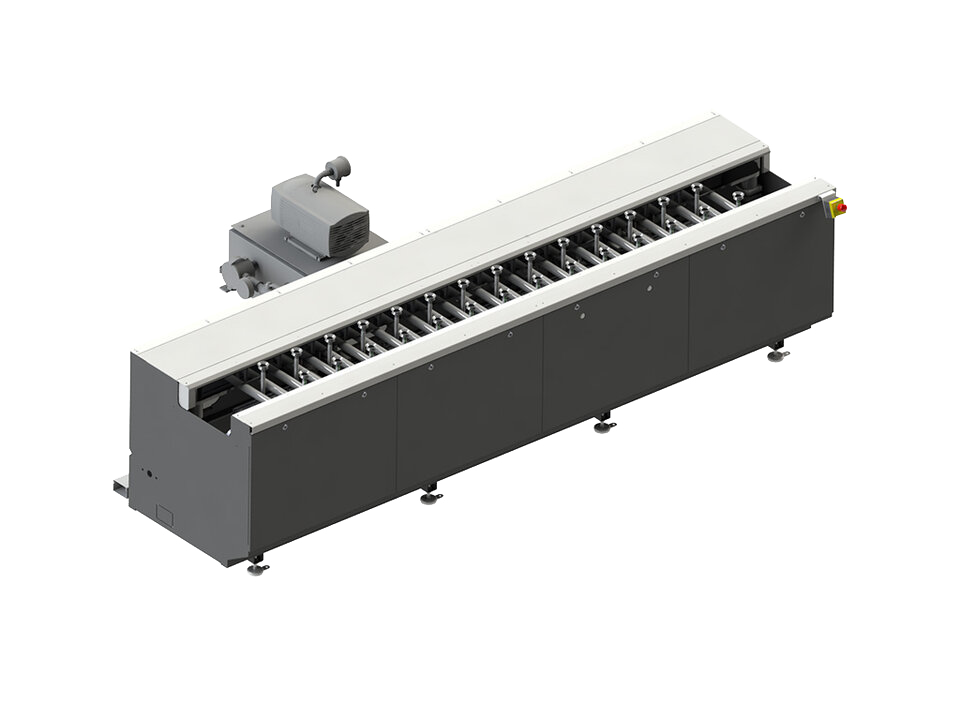

Shrink Wrap Tunnel Systems

Complete shrink-wrapping solutions for packaging applications.

Side Sealing Equipment

Specialized side sealing systems for custom packaging needs.

Packing Station for Doors

Dedicated door packaging solutions for furniture manufacturers.

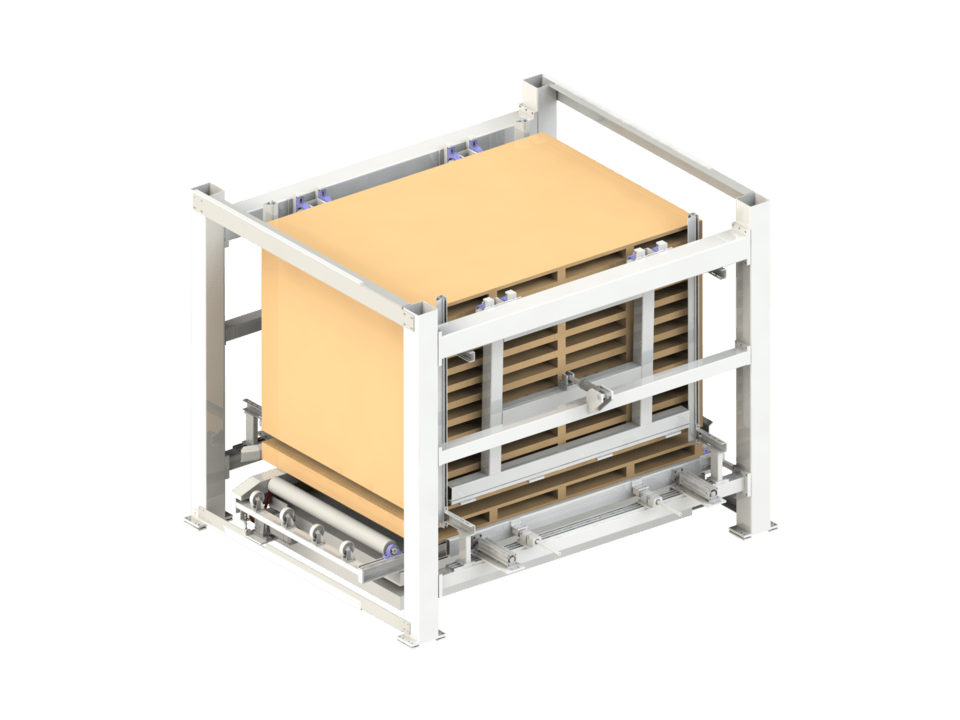

Pallet Stacking and Unstacking Systems

Automated material handling for packaging operations.

IPS - Integrated Packaging Solution

Complete integrated packaging systems for streamlined operations.

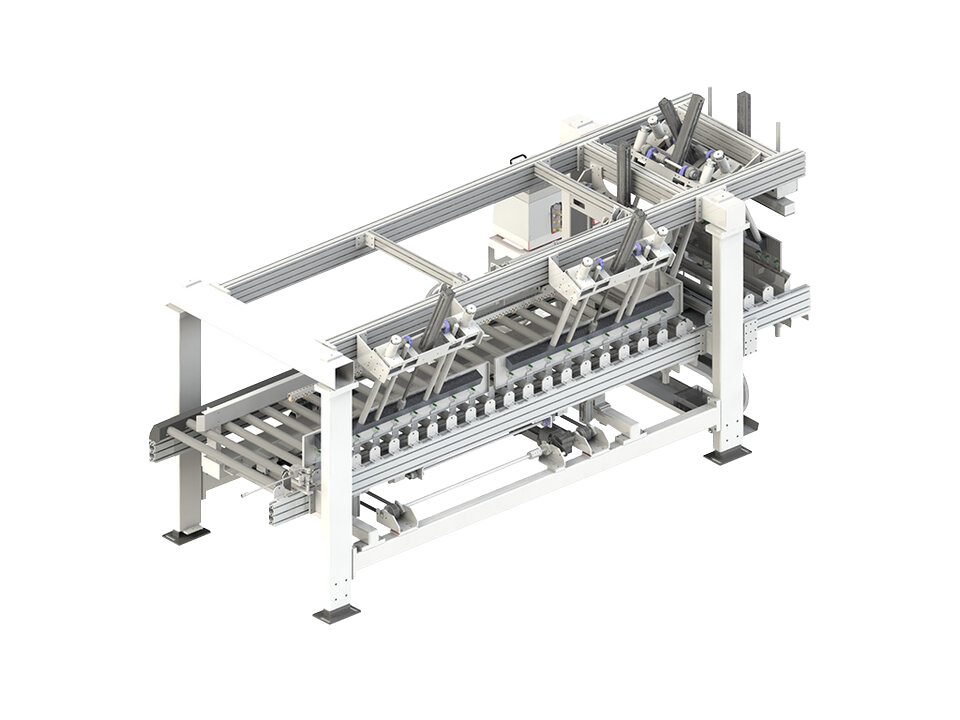

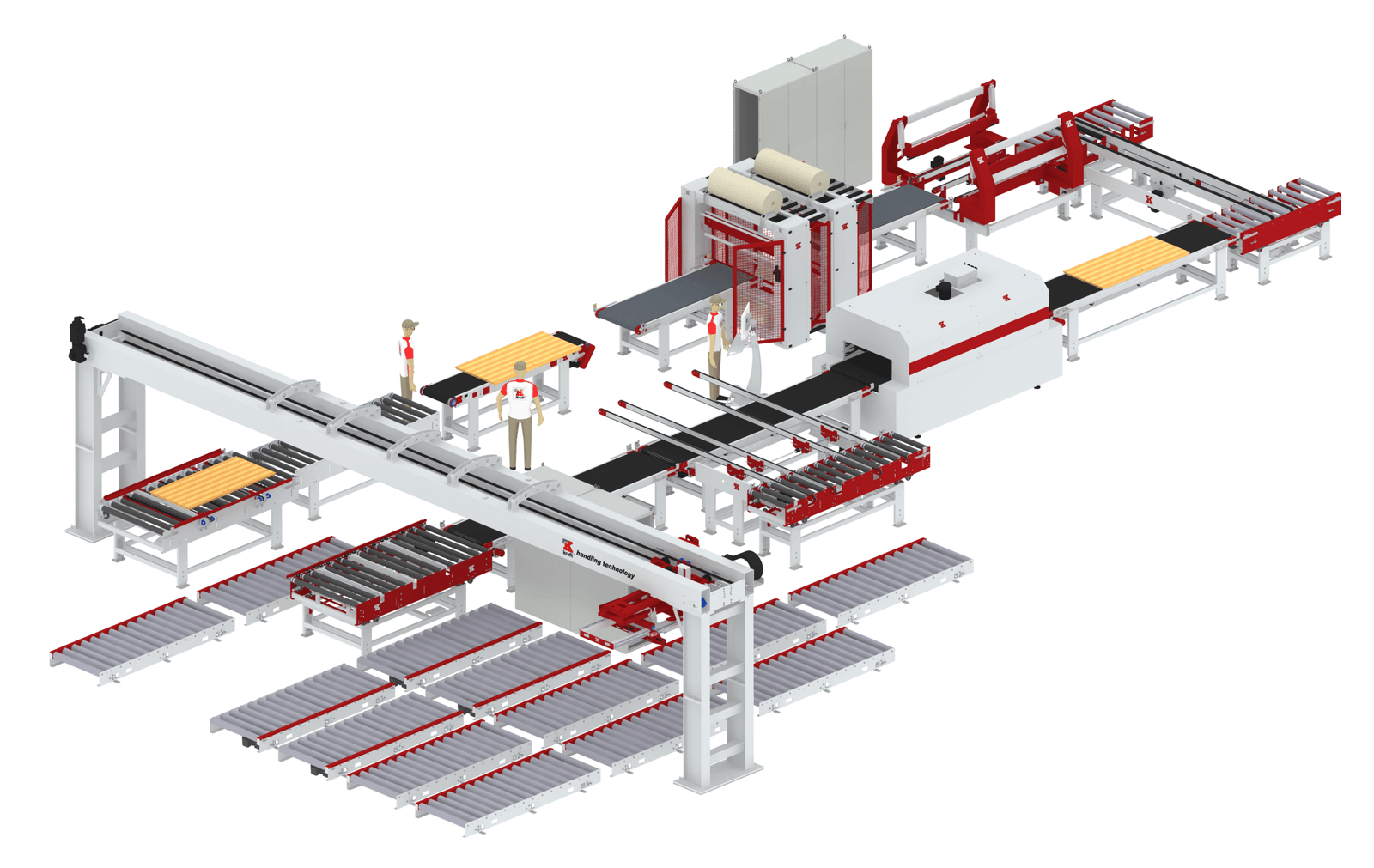

Packaging Solution Application Example

Shrink Wrap Packaging for Doors

Doors with mounted fittings are packaged in film using our comprehensive system. The films are sealed at the longitudinal and front sides, followed by the shrinking process in our shrink wrap tunnel. This automated packaging solution ensures consistent protection and professional presentation of finished doors.

Shrink-wrap area

Angular transfer

Shrink wrap tunnel

Belt conveyor

Film packaging

Manual assembly station

Belt conveyor

Film packaging

Side welding

Roller conveyor

Loading/Stacking/Order picking

Floor roller conveyor

Angular transfer

Roller conveyor